course of meter calibration lab is a specialized facility equipped to perform calibration services on numerous types of process meters. These meters are crucial components in industrial processes, measuring parameters such as pressure, temperature, circulate, and electrical alerts. Here's a breakdown of what a course of meter calibration lab sometimes presents:

Scope of Calibration:

Process meter calibration labs cover a extensive range of devices, including strain gauges, temperature sensors, flow meters, stage transmitters, pH meters, and other units used in industrial processes.

Accreditation and Compliance:

Accreditation from related authorities, such as ISO/IEC 17025, ensures that the calibration lab follows international standards and practices. Compliance with industry laws can be important.

Calibration Standards:

The lab uses extremely accurate and traceable calibration requirements to match and adjust the measurements of the process meters.

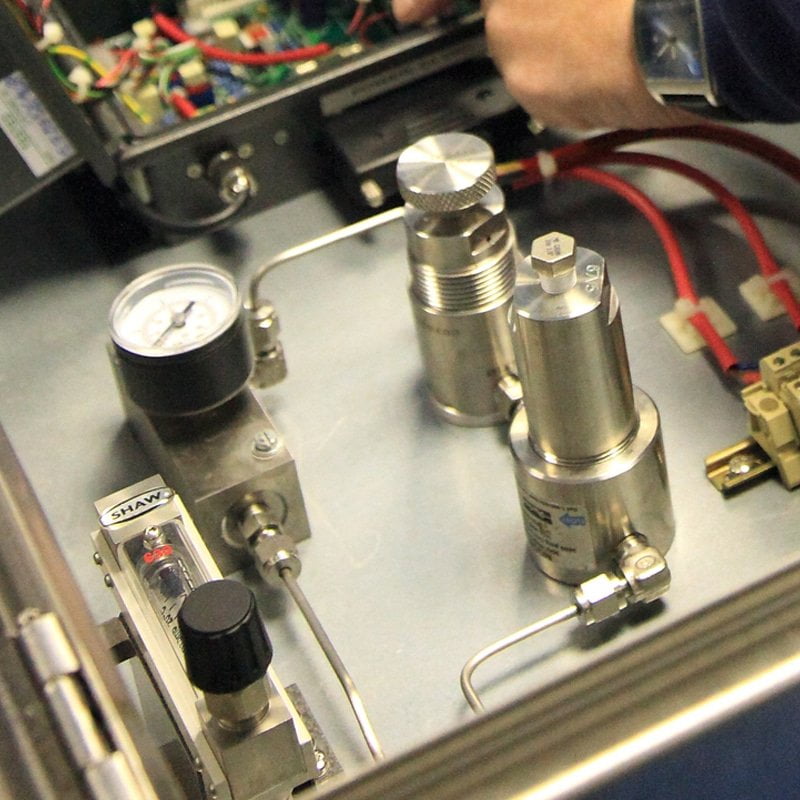

Calibration Equipment:

Specialized calibration gear for pressure, temperature, circulate, and electrical parameters is used to carry out exact calibrations. This equipment may embody calibrators, standards, temperature baths, and different instruments.

Trained Personnel:

Calibration technicians in the lab should be well-trained and skilled in calibrating numerous types of process meters. They must perceive the specs and necessities of different industries.

Traceability:

Traceability is maintained by guaranteeing that the calibration standards used are traceable to national or international requirements. This establishes a clear and documented path from the measurements to a recognized standard.

Documentation and Calibration Certificates:

The lab provides comprehensive documentation for each calibration carried out. Calibration certificates are issued to clients, detailing the conditions earlier than and after calibration, procedures adopted, and other relevant data.

On-Site Calibration Services:

Some labs supply on-site calibration services, minimizing the downtime associated with removing instruments from the industrial process. On-site companies are particularly helpful for crucial processes.

Adjustment and Repair Services:

If a course of meter is discovered to be out of calibration, the lab could provide adjustment or restore providers to deliver it again to the specified accuracy.

Calibration Intervals:

The lab may present suggestions for calibration intervals based on trade standards, tools specifications, and the criticality of the measurements.

Customer Support:

A good calibration lab should offer glorious customer assist, assisting shoppers with inquiries, scheduling calibration services, and addressing any concerns.

Choosing a reputable process meter calibration lab is important for sustaining the accuracy and reliability of commercial instruments. Regular calibration ensures that process meters perform inside specified tolerances, contributing to the general effectivity and security of industrial processes..